Himself has done a very quick turnaround on the balcony handrail for Van 51.

He’s also knocked up a brass roof, which is just resting in place at the moment, and attached a vac hose.

There are still some handrails to be made up, and of course the interior to make.

First, though, I’ll need to uncover some pictures to remind myself what’s actually in there...

Tuesday 31 December 2019

Sunday 29 December 2019

2019 - Part 4

We rounded off the year with a first showing of Bron Hebog in Scotland at our own club's show in Greenock and with the debut of our new set of WWHR carriages.

Unfortunately only Russell is able to pull the whole lot up the hill. Gelert and the Baldwin have to have the load reduced....

130 is really starting to come together, although once again Himself is waiting for the real one to be finished so we can be completely sure about all those little details.

I'd finally got round to making a start on the second WHR Pullman observation car which is being given the name Gwyrfai.

Progress on the carriage has not been rapid but did get most of a day to myself to start adding the beading to the side pieces.

Himself decided that after many years broken on a shelf it was time to get our original Blanche back into running order, a major operation which required the strip down of the chassis and replacement of a gear wheel.

He was also getting on with the very intricate task of lining out the FR Observation car 152, the completion of which has taken most of 2019.

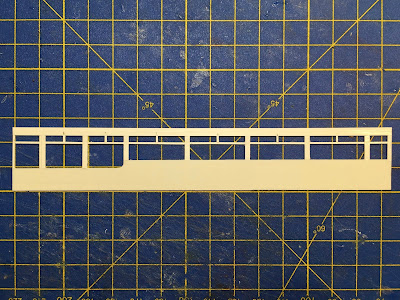

To bring the review up to date, as you've been reading in recent weeks I've been making an effort to complete the first model of van 51, which has sat for many months looking like this.

And Himself celebrated the completion of 152 with a line up of our three Pullman obs, hopefull to be joined by a fourth next year.

Thanks for reading our updates during 2019 and we look forward to sharing more of our modelling with you in 2020.

Unfortunately only Russell is able to pull the whole lot up the hill. Gelert and the Baldwin have to have the load reduced....

130 is really starting to come together, although once again Himself is waiting for the real one to be finished so we can be completely sure about all those little details.

I'd finally got round to making a start on the second WHR Pullman observation car which is being given the name Gwyrfai.

November

Progress on the carriage has not been rapid but did get most of a day to myself to start adding the beading to the side pieces.

Himself decided that after many years broken on a shelf it was time to get our original Blanche back into running order, a major operation which required the strip down of the chassis and replacement of a gear wheel.

He was also getting on with the very intricate task of lining out the FR Observation car 152, the completion of which has taken most of 2019.

December

To bring the review up to date, as you've been reading in recent weeks I've been making an effort to complete the first model of van 51, which has sat for many months looking like this.

And Himself celebrated the completion of 152 with a line up of our three Pullman obs, hopefull to be joined by a fourth next year.

Thanks for reading our updates during 2019 and we look forward to sharing more of our modelling with you in 2020.

Friday 27 December 2019

2019 - Part 3

The summer saw us taking Dduallt for its third showing in nine months, after receiving an invitation to represent the Greenock club at the show in Perth.

This was is up there among one of the best in the country and we're very much looking forward to returning with Bron Hebog in 2020.

June also saw an unexpected opportunity to purchase another Backwoods double fairlie, which Himself duly snapped up and straight away began starting work on a James Spooner, being careful not to get ahead of the real one under construction at Boston Lodge.

The Gladstone Car was also finished with transfers and the illusion of curtains in the central saloon now in place.

We didn't waste any time starting on the next of our WHHR carriages.

Himself soldered up a Worsley Works kit for the buffet car and I was given the job of knocking up an interior in styrene.

James Spooner now had its bogies and firebox (motorbox) complete.

Hot on the heels of the Buffet Car was another brass body shell for the Ashbury corridor carriage in its original form, which we're doing up as the replica built for the WHHR.

There was a little more scenic work done on Bron Hebog ready for its next outing in Greenock in the autumn, with more trees being planted.

By now the WHHR carriages were already being painted.

And Gelert was in the final stages of painting and lining with a lot of extra details being added to the 3D body to really set it off.

This was is up there among one of the best in the country and we're very much looking forward to returning with Bron Hebog in 2020.

June also saw an unexpected opportunity to purchase another Backwoods double fairlie, which Himself duly snapped up and straight away began starting work on a James Spooner, being careful not to get ahead of the real one under construction at Boston Lodge.

The Gladstone Car was also finished with transfers and the illusion of curtains in the central saloon now in place.

August

We didn't waste any time starting on the next of our WHHR carriages.

Himself soldered up a Worsley Works kit for the buffet car and I was given the job of knocking up an interior in styrene.

James Spooner now had its bogies and firebox (motorbox) complete.

Hot on the heels of the Buffet Car was another brass body shell for the Ashbury corridor carriage in its original form, which we're doing up as the replica built for the WHHR.

September

There was a little more scenic work done on Bron Hebog ready for its next outing in Greenock in the autumn, with more trees being planted.

By now the WHHR carriages were already being painted.

And Gelert was in the final stages of painting and lining with a lot of extra details being added to the 3D body to really set it off.

Tuesday 24 December 2019

Sunday 22 December 2019

2019 - Part 2

The next instalment of our review begins in April when I was making the interior for another 'bowsider' which was destined to become number 20 in Col. Stephens green.

Himself was being challenged with building up a prototype chassis for Gelert which we had been asked to test, seen here beneath the Robex 3D printed body.

Some finishing details were being added to observation carriage 152.

Dduallt was back on show just down the road from us in Troon.

I was puzzling out how to fit an interior into the Gladstone carriage while still allowing for the floor to be removed for painting and maintenance.

Carriage 20 was swiftly painted and made its debut on the layout at the show.

I was embarking on a project to create a kit of parts to build the P Way van 51 in its current condition - shown here are the first of the castings for the body.

The chassis on Gelert was progressing with the motion now in place.

And carriage 152 was taken for a first test run on Dduallt.

Fortunately, this time I'd drilled the holes for the bogie pivot bolts in the correct position and it didn't foul the rockface in the cutting beneath Rhoslyn Bridge!

Himself was being challenged with building up a prototype chassis for Gelert which we had been asked to test, seen here beneath the Robex 3D printed body.

Some finishing details were being added to observation carriage 152.

May

Dduallt was back on show just down the road from us in Troon.

I was puzzling out how to fit an interior into the Gladstone carriage while still allowing for the floor to be removed for painting and maintenance.

Carriage 20 was swiftly painted and made its debut on the layout at the show.

June

I was embarking on a project to create a kit of parts to build the P Way van 51 in its current condition - shown here are the first of the castings for the body.

The chassis on Gelert was progressing with the motion now in place.

And carriage 152 was taken for a first test run on Dduallt.

Fortunately, this time I'd drilled the holes for the bogie pivot bolts in the correct position and it didn't foul the rockface in the cutting beneath Rhoslyn Bridge!

Labels:

152,

20,

Bowsiders,

Carriage Interiors,

Carriages,

Dduallt,

Exhibitions,

Gelert,

Gladstone Carriage,

Robex,

Worsley Works

Friday 20 December 2019

2019 - Part 1

Every December I like to take a look back at all that we've achieved between us in the last year. (Mostly Himself, if we're being honest...)

In January of this year our 4th NGG16, 143, was on the test track still in brass.

There were more carriages on the workbench, with brass roofs being made for the second of the superbarn Observation Cars and another of the saloons.

Himself had also started assembling a Worsley Works bowsider 17, to give us a model in the current colours.

A few weeks later and the superbarn saloon was almost ready for varnishing.

We'd also begun putting together a Worsley Works NWNGR Gladstone Carriage as the first stage in a WHHR rake.

By this stage the Garratt was well through the painting process.

17 had also been varnished and is pictured on Ddaullt.

And we ended the first quarter of the year with Himself starting on the 5th Garratt, destined to be 130.

In January of this year our 4th NGG16, 143, was on the test track still in brass.

There were more carriages on the workbench, with brass roofs being made for the second of the superbarn Observation Cars and another of the saloons.

Himself had also started assembling a Worsley Works bowsider 17, to give us a model in the current colours.

February

A few weeks later and the superbarn saloon was almost ready for varnishing.

We'd also begun putting together a Worsley Works NWNGR Gladstone Carriage as the first stage in a WHHR rake.

By this stage the Garratt was well through the painting process.

March

By the begining of the next month it was finished and taking a test run with sister 138

17 had also been varnished and is pictured on Ddaullt.

And we ended the first quarter of the year with Himself starting on the 5th Garratt, destined to be 130.

Labels:

130,

143,

152,

17,

Backwoods Miniatures,

Garratts,

Gladstone Carriage,

Locomotives,

NGG16,

Worsley Works

Wednesday 18 December 2019

Moonlighting Again

Himself has been waylaid again and has been working on more 3mm scale standard gauge models as a favour to the Engineering Consultant.

Currently he’s building up this GWR 2-8-0 Prairie which is mostly etched brass with a very neat resin casting for the boiler.

He was explaining to me that it bears a similarity to the Mercian kit for our Welsh Pony in that the etches are scaled down from a 7mm kit and as a consequence the motor doesn’t fit!

It also has a very agricultural drive with the motor mounted vertically with a worm driving a big gear mounted on the axle - no reduction gearbox here!

Surfice to say he’s overcome this issue and the build is progressing nicely, but counting and pressing out all the rivers on those tanks was a thankless task apparently....

Currently he’s building up this GWR 2-8-0 Prairie which is mostly etched brass with a very neat resin casting for the boiler.

He was explaining to me that it bears a similarity to the Mercian kit for our Welsh Pony in that the etches are scaled down from a 7mm kit and as a consequence the motor doesn’t fit!

It also has a very agricultural drive with the motor mounted vertically with a worm driving a big gear mounted on the axle - no reduction gearbox here!

Surfice to say he’s overcome this issue and the build is progressing nicely, but counting and pressing out all the rivers on those tanks was a thankless task apparently....

Monday 16 December 2019

Genesis

I discovered a real blast from the past while checking with in Himself yesterday - my orginal concept plan for Dduallt I made when I was still at school.

It was a proper, scale, 3D model made using very sophisticated materials - cardboard and millput!

It was a very useful exercise because there were a couple of major revisions we made when we built if for real.

At the front we chopped off the left hand corner which was just empty scenic space to give the layout its distinctive wedge shape which draws the eye to Rhoslyn Bridge.

We also revised the fiddle yard plans so have two separate yards at right angles to the layout instead of attempting putting them in parallel behind, which would have made it much harder to operate.

There was also a rather unrealistic idea for a ski ramp linking the two levels to give a continuous run option.

It was a proper, scale, 3D model made using very sophisticated materials - cardboard and millput!

It was a very useful exercise because there were a couple of major revisions we made when we built if for real.

At the front we chopped off the left hand corner which was just empty scenic space to give the layout its distinctive wedge shape which draws the eye to Rhoslyn Bridge.

We also revised the fiddle yard plans so have two separate yards at right angles to the layout instead of attempting putting them in parallel behind, which would have made it much harder to operate.

There was also a rather unrealistic idea for a ski ramp linking the two levels to give a continuous run option.

Friday 13 December 2019

More Unfinished Business

The election - and the acute sleep deprivation which goes with it - has delayed me posting today.

In the absence of any fresh modelling activity - and with Himself just returned from volunteering on the FR - there’s nothing new to tell you, so how about some pictures of another model which still awaits final completion?

Our Backwoods Lyn made its debut at Dinas last year in naked brass and white metal but still awaits painting.

This is not a unsubtle hint to Himself because he has been prioritising other projects.

Eventually it would look something like this.

I suppose the question is whether ours is outshopped before the Heljan model appears?

In the absence of any fresh modelling activity - and with Himself just returned from volunteering on the FR - there’s nothing new to tell you, so how about some pictures of another model which still awaits final completion?

Our Backwoods Lyn made its debut at Dinas last year in naked brass and white metal but still awaits painting.

This is not a unsubtle hint to Himself because he has been prioritising other projects.

Eventually it would look something like this.

I suppose the question is whether ours is outshopped before the Heljan model appears?

Wednesday 11 December 2019

On Hold

I had marked today down in the diary to get some modelling done, but a couple of things got in the way.

Firstly, a combination of the General Election and an acute staffing crisis means I'll have to spend the day in the office rather than on holiday.

Secondly, Himself made me send Glaslyn back for a photoshoot (see previous post) meaning I've lost my vital reference for Gwyrfai, which still needs the end pieces made.

It reminds me that there's another project which is on hold, which is my Van 51.

I cast the body shell parts with the intention of being able to produce it as a kit, but it has been stalled for a number of months while I wait for an etched part for the handrail to be made for me.

I'm getting to thinking that the best thing might be to pass it over to Himself who'll be able to knock up a bespoke one with his soldering iron and we can at least get one new model for Bron Hebog even if the kit never ends up going on sale.

It'll go very nicely on our Bridge Inspection Trains, so beloved of the Engineering Consultant.

When he's not helping us operate Bron Hebog he can be found organising the real trains around Porthmadog Harbour Station.

It's a good job the person who signed him off as a signalman never witnessed the chaotic state of the fiddle yards on Bron Hebog and Dduallt when he's left in charge of them....

Firstly, a combination of the General Election and an acute staffing crisis means I'll have to spend the day in the office rather than on holiday.

Secondly, Himself made me send Glaslyn back for a photoshoot (see previous post) meaning I've lost my vital reference for Gwyrfai, which still needs the end pieces made.

It reminds me that there's another project which is on hold, which is my Van 51.

I cast the body shell parts with the intention of being able to produce it as a kit, but it has been stalled for a number of months while I wait for an etched part for the handrail to be made for me.

I'm getting to thinking that the best thing might be to pass it over to Himself who'll be able to knock up a bespoke one with his soldering iron and we can at least get one new model for Bron Hebog even if the kit never ends up going on sale.

It'll go very nicely on our Bridge Inspection Trains, so beloved of the Engineering Consultant.

When he's not helping us operate Bron Hebog he can be found organising the real trains around Porthmadog Harbour Station.

It's a good job the person who signed him off as a signalman never witnessed the chaotic state of the fiddle yards on Bron Hebog and Dduallt when he's left in charge of them....

Monday 9 December 2019

Peckett Pics

A few days ago one of our readers asked to see more pictures of our Peckett Harrogate and so I’ve dug back through the archive to find these.

For those who don’t know the background this is a famous ‘might have been’ from the early days of the FR revival.

It was built for service at Harrogate gas works - with a much more restrictive cab profile than the one it now sports - and was brought to the FR as a potential solution to the motive power crisis in the late 1950s.

Linda and Blanche turned up a couple years later and that was that for Peckett which was sold 30 years after its arrival having never seen service.

A stripped down chassis did make some exploratory adventures up the Vale shortly before its departure, but they only confirmed its unsuitability for the line.

There was a Hollywood ending, though.

Eventually it landed up at Statfold, acquired its new name, and steamed on the FR as a gala visitor - albeit only between Blaenau Ffestiniog and Tanygrisiau.

It also did some gala runs on the Welsh Highland up to Waunfawr, and a little application of Rule 1 sees us running it on Bron Hebog and Dduallt.

The kit is by RT models, and it's a little cracker.

Perfect running is guaranteed by the Farish 08 chassis and some simple etched motion parts.

The body is made up of a big lump of a white metal casting and a nicely produced brass etch for the cab and fake frames.

With all that weight sitting above on a simple, reliable chassis, it's just about all you could ask for in a OO9 locomotive.

Himself added some extra detailing, as he always does, such as the vac and air brake pipes, which really set it off.

With no lining, aside from the letters on the saddle tank, it was probably also his favourite locomotive to paint.

(Since our model was made the loco now bears the legend 'Statfold Barn Railway' which means Himself has had a lucky escape!)

For those who don’t know the background this is a famous ‘might have been’ from the early days of the FR revival.

It was built for service at Harrogate gas works - with a much more restrictive cab profile than the one it now sports - and was brought to the FR as a potential solution to the motive power crisis in the late 1950s.

Linda and Blanche turned up a couple years later and that was that for Peckett which was sold 30 years after its arrival having never seen service.

A stripped down chassis did make some exploratory adventures up the Vale shortly before its departure, but they only confirmed its unsuitability for the line.

There was a Hollywood ending, though.

Eventually it landed up at Statfold, acquired its new name, and steamed on the FR as a gala visitor - albeit only between Blaenau Ffestiniog and Tanygrisiau.

It also did some gala runs on the Welsh Highland up to Waunfawr, and a little application of Rule 1 sees us running it on Bron Hebog and Dduallt.

The kit is by RT models, and it's a little cracker.

Perfect running is guaranteed by the Farish 08 chassis and some simple etched motion parts.

The body is made up of a big lump of a white metal casting and a nicely produced brass etch for the cab and fake frames.

With all that weight sitting above on a simple, reliable chassis, it's just about all you could ask for in a OO9 locomotive.

Himself added some extra detailing, as he always does, such as the vac and air brake pipes, which really set it off.

With no lining, aside from the letters on the saddle tank, it was probably also his favourite locomotive to paint.

(Since our model was made the loco now bears the legend 'Statfold Barn Railway' which means Himself has had a lucky escape!)

Saturday 7 December 2019

Triplets

We can’t manage a line up of four Pullman observation cars like the FR did recently at Harbour Station, but watch this space....

Himself decided a little photo call was in order after the final assembly of 152, posed in the fiddle yard with 150 (not named Gwynedd in Bron Hebog-land, and Glaslyn.

The design change to 152 with the two pillars at the front was on account of customer feedback from 150 with its single post in the middle.

It’s a convenient way of quickly telling which is which but I still can’t decide which I prefer.

Himself decided a little photo call was in order after the final assembly of 152, posed in the fiddle yard with 150 (not named Gwynedd in Bron Hebog-land, and Glaslyn.

The design change to 152 with the two pillars at the front was on account of customer feedback from 150 with its single post in the middle.

It’s a convenient way of quickly telling which is which but I still can’t decide which I prefer.

Labels:

150,

152,

Glaslyn,

Observation Carriages,

Pullman Carriages

Subscribe to:

Posts (Atom)