The time has come to put roofs on the second and third of the Super Barns I'm building.

Alas, that entails purchasing another can of alcoholic beverage and emptying the said container. Oh, the sacrifice!

So the project is crawling towards completion. These roofs need to be primed and fixed in place, and then footsteps and vac pipes will be added.

Thursday 30 January 2014

Tuesday 28 January 2014

Reinforcements

A short update for you today.

Himself has had to make some alterations to the Backwoods kit for the new Garratt as a consequence of adapting it to represent 138.

Shortening the length of the rear unit bunker has exposed a weakness in the frame where, when constructed as intended, the tank should be attached with some screws.

So he has added some strengthening pieces under the frame where it tended to bend a little.

I anticipate a more significant update on this project later this week.

Himself has had to make some alterations to the Backwoods kit for the new Garratt as a consequence of adapting it to represent 138.

Shortening the length of the rear unit bunker has exposed a weakness in the frame where, when constructed as intended, the tank should be attached with some screws.

So he has added some strengthening pieces under the frame where it tended to bend a little.

I anticipate a more significant update on this project later this week.

Sunday 26 January 2014

Water Tank & Wiggly Bits

So, it appears the secret is out.

Our latest NGG16 will be a model of 138 as running around on the WHR currently in lined red livery, coal-fired with the big single headlamps.

An eagle-eyed reader noticed the filenames of the photographs on the last blog post on this model and blurted it out on the Bron Hebog Facebook page. (Have you 'liked' it yet?)

In the meantime Himself has begun work on the front end, building up the frame for the power unit and altering the water tank which has had to have its rivets filed off.

Here's the back view.

He's also begun tackling one of the trickiest bits of the kit - assembling the Walschaerts valve gear.

This picture shows one of the four sets joined together and, by way of illustration, the parts required laid out next to it.

What is does not show, as Himself pointed out to me in his email, is the patience required to put it together.

Indeed!

Our latest NGG16 will be a model of 138 as running around on the WHR currently in lined red livery, coal-fired with the big single headlamps.

An eagle-eyed reader noticed the filenames of the photographs on the last blog post on this model and blurted it out on the Bron Hebog Facebook page. (Have you 'liked' it yet?)

In the meantime Himself has begun work on the front end, building up the frame for the power unit and altering the water tank which has had to have its rivets filed off.

Here's the back view.

He's also begun tackling one of the trickiest bits of the kit - assembling the Walschaerts valve gear.

This picture shows one of the four sets joined together and, by way of illustration, the parts required laid out next to it.

What is does not show, as Himself pointed out to me in his email, is the patience required to put it together.

Indeed!

Friday 24 January 2014

Superstition

Do you ever get the feeling that some models are fated? I'm coming to believe that there's some kind of curse on my Super Barns.

If you've read this blog from the beginning then you may recall on the first one I made - a styrene model of 103 - I discovered late on the build that the drawings I was using bore no relation to the actual carriage. All the window pillars were in the wrong place.

I had to conduct a surgical operation to remove the carriage sides and graft on a replacement pair with the correct dimensions.

Well, blow me if it hasn't happened again on my resin Super Barn production line.

I was working away steadily on the fourth of these carriages (being built for clients) gluing the struts for the truss rods in place on the underframe when I noticed the brackets along one side of the frame were in a different place to those one of the other carriages I was using as a guide.

These brackets are all in line with the window pillars.

I was flummoxed. I could not understand what was going on. Then it began to dawn on me that I'd made a very silly mistake in casting and assembling the parts for this carriage.

The thing about the Super Barns is the two sides are not symmetrical - they are a mirror image of each other - there is a left hand casting and a right hand casting.

(Or a Clock and an Engine side casting in Boston Lodge parlance.)

Eventually I realised that I had made this one up with two of the same type of casting instead of one of each.

And it gets worse.

"No problem", I thought.

I had a couple of extra sides sitting on the shelf because I've still got a 5th one to make, so I thought I could just borrow one of those,

I wasted another 15 minutes clearing the flash out from the windows until I discovered that this was the same type as the faulty one I'd just removed, and so was the other spare on the shelf.

It turns out I somehow managed to produce 4 from the same mould in my last casting session instead of two pairs.

So progress has been halted for a day or so while I cast another two replacements from the opposite mould, and I have triple checked it's the right one this time.

If you've read this blog from the beginning then you may recall on the first one I made - a styrene model of 103 - I discovered late on the build that the drawings I was using bore no relation to the actual carriage. All the window pillars were in the wrong place.

I had to conduct a surgical operation to remove the carriage sides and graft on a replacement pair with the correct dimensions.

Well, blow me if it hasn't happened again on my resin Super Barn production line.

I was working away steadily on the fourth of these carriages (being built for clients) gluing the struts for the truss rods in place on the underframe when I noticed the brackets along one side of the frame were in a different place to those one of the other carriages I was using as a guide.

These brackets are all in line with the window pillars.

I was flummoxed. I could not understand what was going on. Then it began to dawn on me that I'd made a very silly mistake in casting and assembling the parts for this carriage.

The thing about the Super Barns is the two sides are not symmetrical - they are a mirror image of each other - there is a left hand casting and a right hand casting.

(Or a Clock and an Engine side casting in Boston Lodge parlance.)

Eventually I realised that I had made this one up with two of the same type of casting instead of one of each.

And it gets worse.

"No problem", I thought.

I had a couple of extra sides sitting on the shelf because I've still got a 5th one to make, so I thought I could just borrow one of those,

I wasted another 15 minutes clearing the flash out from the windows until I discovered that this was the same type as the faulty one I'd just removed, and so was the other spare on the shelf.

It turns out I somehow managed to produce 4 from the same mould in my last casting session instead of two pairs.

So progress has been halted for a day or so while I cast another two replacements from the opposite mould, and I have triple checked it's the right one this time.

Wednesday 22 January 2014

Bunker Shots

Himself has started on the bodywork of our new Garratt and the first task has been some modifications to the rear tank / bunker which has needed to be shortened at the front and the cut-outs at the back have had to be elongated.

Much to the disgust of the designer of the Backwoods kit, no doubt, the rivets have had to be filed off as this locomotive now has welded tanks fore and aft.

Because the front of the tank is shorter, the screws and lugs which attach it to the running plate can't be used so they have just been bent round to clip under the plate. This is to stop the front of the tank lifting up. The rear attachment is still the same.

The front tank will also require the rivets to be taken off and the cut out altered.

Here you can see it sitting on the rolling chassis with the connecting rod temporarily in place.

It's very exciting to see this 3rd NGG16 taking shape and I hope you're going to enjoy this detailed account of building one of these magnificent kits.

Much to the disgust of the designer of the Backwoods kit, no doubt, the rivets have had to be filed off as this locomotive now has welded tanks fore and aft.

Because the front of the tank is shorter, the screws and lugs which attach it to the running plate can't be used so they have just been bent round to clip under the plate. This is to stop the front of the tank lifting up. The rear attachment is still the same.

The front tank will also require the rivets to be taken off and the cut out altered.

Here you can see it sitting on the rolling chassis with the connecting rod temporarily in place.

It's very exciting to see this 3rd NGG16 taking shape and I hope you're going to enjoy this detailed account of building one of these magnificent kits.

Monday 20 January 2014

Readers Letters

It's always nice to read the comments you leave on the blog.

No, really, it is. We've been doing this for a couple of years now and haven't yet been attacked by any narrow gauge trolls (if such things exist) although web crawlers and bots are another matter..

Anyhow, the purpose of this post is to reply to a comment left by Metroman a few days ago who asked whether our latest Backwoods NGG16 kit is one of the current ones with plastic crank bushes.

I have received word back from Himself who tells me it is, and has supplied photographic evidence to prove the point.

However, he tells me that he has tinkered with the kit because he's not happy with the security of the cranks on the axle ends, so has reverted to soldering them into place on one side as he has done with our existing pair of Garratts.

He does point out that once you have reamed out the cranks to accept plastic bushes you lose the option of soldering them on unless you ask Pete very, very nicely, for some new cranks.

I trust that answers Metroman's question adequately.

No, really, it is. We've been doing this for a couple of years now and haven't yet been attacked by any narrow gauge trolls (if such things exist) although web crawlers and bots are another matter..

Anyhow, the purpose of this post is to reply to a comment left by Metroman a few days ago who asked whether our latest Backwoods NGG16 kit is one of the current ones with plastic crank bushes.

I have received word back from Himself who tells me it is, and has supplied photographic evidence to prove the point.

However, he tells me that he has tinkered with the kit because he's not happy with the security of the cranks on the axle ends, so has reverted to soldering them into place on one side as he has done with our existing pair of Garratts.

He does point out that once you have reamed out the cranks to accept plastic bushes you lose the option of soldering them on unless you ask Pete very, very nicely, for some new cranks.

I trust that answers Metroman's question adequately.

Saturday 18 January 2014

Peckett Preview

You'll have to forgive the background to the picture - Himself had been nibbling at his brandy-laced Xmas cake when he took the snap a few weeks ago - but here's a shot showing progress with painting the Peckett 'Harrogate'.

Himself says he's getting quite fond of this wee beastie and it might end up seeing a lot more action on Bron Hebog that it has on the real WHR.

Himself says he's getting quite fond of this wee beastie and it might end up seeing a lot more action on Bron Hebog that it has on the real WHR.

Thursday 16 January 2014

Patience Is A Virtue

Once a year my long-term project to build a second model of the WHR's KMX Tamper takes a big leap forward before gathering dust again for the next 11 months.

This is not entirely my fault. For most of the last year I've been waiting on Himself to bend and solder a few bits of brass together into the shape of a roof.

Finally the nagging has paid off...

As you can see our existing KMX has been used as a template and Himself has managed a very good copy of the original.

When I get the tamper back the remaining jobs will be to add the external details onto the bogies such as the outboard disc brakes.

It is just possible that it might even be finished and delivered to the client this year.

This is not entirely my fault. For most of the last year I've been waiting on Himself to bend and solder a few bits of brass together into the shape of a roof.

Finally the nagging has paid off...

As you can see our existing KMX has been used as a template and Himself has managed a very good copy of the original.

When I get the tamper back the remaining jobs will be to add the external details onto the bogies such as the outboard disc brakes.

It is just possible that it might even be finished and delivered to the client this year.

Tuesday 14 January 2014

Seats Again

The resin's been out again.

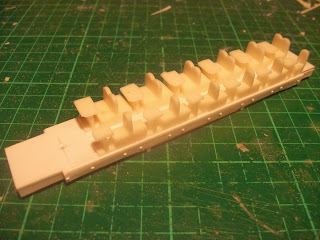

I've got 3 Super Barn models on the go on the workbench at the moment - 2 of them for a client and one of them for me - and these are the seat & table sets for the 2nd and 3rd of them.

I'm pleased with the way these have turned out.

They're proving quite simple to cast with very few rejects. I've also pushed the boat out and made a second mould to double the production rate.

That's not as silly a statement as might first appear because due to the height of these sets they swallow quite a lot of RTV to make each mould given the size of the casting you're actually producing.

However, they do make it a lot simpler, and a lot less mind-numbing to fit out a carriage interior as opposed to making each of them by hand.

I've got 3 Super Barn models on the go on the workbench at the moment - 2 of them for a client and one of them for me - and these are the seat & table sets for the 2nd and 3rd of them.

I'm pleased with the way these have turned out.

They're proving quite simple to cast with very few rejects. I've also pushed the boat out and made a second mould to double the production rate.

That's not as silly a statement as might first appear because due to the height of these sets they swallow quite a lot of RTV to make each mould given the size of the casting you're actually producing.

However, they do make it a lot simpler, and a lot less mind-numbing to fit out a carriage interior as opposed to making each of them by hand.

Sunday 12 January 2014

Mr Punch

Himself has got work on our new Backwoods Garratt kit underway. There's, erm, quite a lot of it....

One of the first tasks is to complete the pressing out of the rivets which are marked by half etched holes.

I guess many readers may already know that you can buy rivet punching tools but economy is always the watch word on Bron Hebog and why buy when you can adapt?

These days when he's not modelling, or building various bits of the real FR, Himself still moonlights as a Piano Tuner to top up his meagre pension.

So to press out the rivets he has been using one of the tools of the trade for punching out pins that hold together parts of the internal contraption that makes the hammers hit the strings when you press the keys. (a piano action as it's properly known)

He says it works pretty well - better than doing them by hand - although the hole in the brass plate on the base would be better being a little smaller, but the results are very satisfactory to my untrained eye.

This is a snap of the front unit running plate made up.

And a shot here of the frames with the bearings, spring overlays and brake pull rods attached. I've been told to point out to you that you can see that the frames have not deformed around the rivets through using his punch.

You'll notice that I still haven't told you which Garratt this is going to be - I shall keep you in suspense a little longer.

One of the first tasks is to complete the pressing out of the rivets which are marked by half etched holes.

I guess many readers may already know that you can buy rivet punching tools but economy is always the watch word on Bron Hebog and why buy when you can adapt?

These days when he's not modelling, or building various bits of the real FR, Himself still moonlights as a Piano Tuner to top up his meagre pension.

So to press out the rivets he has been using one of the tools of the trade for punching out pins that hold together parts of the internal contraption that makes the hammers hit the strings when you press the keys. (a piano action as it's properly known)

He says it works pretty well - better than doing them by hand - although the hole in the brass plate on the base would be better being a little smaller, but the results are very satisfactory to my untrained eye.

This is a snap of the front unit running plate made up.

And a shot here of the frames with the bearings, spring overlays and brake pull rods attached. I've been told to point out to you that you can see that the frames have not deformed around the rivets through using his punch.

You'll notice that I still haven't told you which Garratt this is going to be - I shall keep you in suspense a little longer.

Friday 10 January 2014

Reassuringly Inexpensive

There are times when you have to make sacrifices for the sake of your art as a scratch builder and this one was particularly taxing.

You see, putting a roof on the Super Barn carriages has necessitated the consumption of a pint of beer.

It's a tough life!

The beer was selected not on the criterion of taste but on the fact it was available in an extra large can, which, as you can see, is almost exactly the same length as a Super Barn carriage.

It's a new departure for me and idea I got from reading entries on a Narrow Gauge modelling forum

Himself is very sniffy about this, on two counts.

Firstly because he doesn't approve of the beer - neither does the Artistic Director for that matter - but also because he thinks slicing up an aluminum tin is a rather second-rate way of modelling a carriage roof.

Normally I make my roofs out of styrene, but the problem with the Super Barns is they have a section of unsupported roof at each end above the inset doors which is very had to replicate in styrene unless you've gone to the bother of heat treating it.

On our model of 121 Himself made a brass roof skin. It worked very well but I wasn't too keen on doing it that way this time because I don't get on with bending brass and I doubt my clients would be happy to wait the time it would take to get him to do it for me!

So I thought I'd try the tin can approach.

Having drained the contents of the can - an essential first step which I want you to know gave me no pleasure at all - I set about hacking it into roof-size strips.

I sliced the ends off with a cutting disc in the mini-drill before attacking the tube which was left with ordinary scissors.

I was worried about whether it would crinkle and curl during this operation but to my delight it didn't, and it kept its curve.

Here you see it resting on top of the carriage.

I have still used my normal roof support structure with a flat section keeping carriage sides in place and a longitudinal rib which means the thin tin has plenty of support.

Glued into position and given a coat of primer this is the finished effect.

I think I'm reasonably happy with that. Cheers!

You see, putting a roof on the Super Barn carriages has necessitated the consumption of a pint of beer.

It's a tough life!

The beer was selected not on the criterion of taste but on the fact it was available in an extra large can, which, as you can see, is almost exactly the same length as a Super Barn carriage.

It's a new departure for me and idea I got from reading entries on a Narrow Gauge modelling forum

Himself is very sniffy about this, on two counts.

Firstly because he doesn't approve of the beer - neither does the Artistic Director for that matter - but also because he thinks slicing up an aluminum tin is a rather second-rate way of modelling a carriage roof.

Normally I make my roofs out of styrene, but the problem with the Super Barns is they have a section of unsupported roof at each end above the inset doors which is very had to replicate in styrene unless you've gone to the bother of heat treating it.

On our model of 121 Himself made a brass roof skin. It worked very well but I wasn't too keen on doing it that way this time because I don't get on with bending brass and I doubt my clients would be happy to wait the time it would take to get him to do it for me!

So I thought I'd try the tin can approach.

Having drained the contents of the can - an essential first step which I want you to know gave me no pleasure at all - I set about hacking it into roof-size strips.

I sliced the ends off with a cutting disc in the mini-drill before attacking the tube which was left with ordinary scissors.

I was worried about whether it would crinkle and curl during this operation but to my delight it didn't, and it kept its curve.

Here you see it resting on top of the carriage.

I have still used my normal roof support structure with a flat section keeping carriage sides in place and a longitudinal rib which means the thin tin has plenty of support.

Glued into position and given a coat of primer this is the finished effect.

I think I'm reasonably happy with that. Cheers!

Wednesday 8 January 2014

Uses For A Coffee Stirrer #197

It's strange how sometimes the most mundane objects can become indispensable modelling tools.

Take, for example, the humble wooden coffee stirrer.

I have a stash of these (liberated from my work canteen when it was closing) which I find handy for mixing the two part resin for casting kit parts

The stuff sticks like sugar to a blanket (or a similar phrase) and so it's best to have something disposable to use because you only get a handful of mixes out of each stick before the tip becomes entombed in a blob of hard resin.

I found another use for one of them the other day when I began the fiddly task of soldering up a batch of handrails for the first of my trio of Super Barns.

These handrails are a bit of a pain in the posterior to model because they have a T joint at each end where they fix onto the carriage body rather than a simple 90 degree bend like any sensible designer would have used, which would be nice and easy to model.

In order to keep burnt finger tips to a minimum, and to ensure they're all produced to the same dimensions, it makes sense to have a jig which does two jobs at the same time.

This is where the coffee stirrer comes in....

By carefully drilling two holes in the side of the stick - there's just a enough meat on them to put a 0.5mm hole in there - I can insert two small lengths of wire which will be held firmly in place while I offer up a longer length of wire and make two quick solder joints.

And voila! A handrail.

Here's how they look in place on the carriage.

So, that's one down - only another 23 to go...

Take, for example, the humble wooden coffee stirrer.

I have a stash of these (liberated from my work canteen when it was closing) which I find handy for mixing the two part resin for casting kit parts

The stuff sticks like sugar to a blanket (or a similar phrase) and so it's best to have something disposable to use because you only get a handful of mixes out of each stick before the tip becomes entombed in a blob of hard resin.

I found another use for one of them the other day when I began the fiddly task of soldering up a batch of handrails for the first of my trio of Super Barns.

These handrails are a bit of a pain in the posterior to model because they have a T joint at each end where they fix onto the carriage body rather than a simple 90 degree bend like any sensible designer would have used, which would be nice and easy to model.

In order to keep burnt finger tips to a minimum, and to ensure they're all produced to the same dimensions, it makes sense to have a jig which does two jobs at the same time.

This is where the coffee stirrer comes in....

By carefully drilling two holes in the side of the stick - there's just a enough meat on them to put a 0.5mm hole in there - I can insert two small lengths of wire which will be held firmly in place while I offer up a longer length of wire and make two quick solder joints.

And voila! A handrail.

Here's how they look in place on the carriage.

So, that's one down - only another 23 to go...

Monday 6 January 2014

On the Twelfth Day Of Christmas...

....Himself sent to me.

An almost-finished We-elsh Po-ny.

(Try singing it!)

It looks pretty impressive, doesn't it! Although all it not what it seems - various parts (such as the cab roof) are only placed in position and there are other things to alter, such as making the dome wonky! And the mount for the nameplate at the front of the saddle tank as well,

If you've been following the build on this blog then you'll know that it's been an absolute swine to assemble and motorise, but you cannot deny that this Mercian Models kit does make a very convincing representation of my favourite breed of FR locomotive.

Himself tells me there is a little bit of attention needed to the chassis because at least of the one wheels revolves with a distinct wobble so he's going to have to attempt some improvised tyre turning with the chassis running, because he is not about to disassemble the motion and attempt to remove the wheel and turn it on a lathe.

The model is also likely to spent a couple of years in primer because we will wait until the real Welsh Pony is restored to steam to be certain of the correct livery.

Remember the Golden Rule of modelling. Never - ever - second-guess the FR!

An almost-finished We-elsh Po-ny.

(Try singing it!)

It looks pretty impressive, doesn't it! Although all it not what it seems - various parts (such as the cab roof) are only placed in position and there are other things to alter, such as making the dome wonky! And the mount for the nameplate at the front of the saddle tank as well,

If you've been following the build on this blog then you'll know that it's been an absolute swine to assemble and motorise, but you cannot deny that this Mercian Models kit does make a very convincing representation of my favourite breed of FR locomotive.

Himself tells me there is a little bit of attention needed to the chassis because at least of the one wheels revolves with a distinct wobble so he's going to have to attempt some improvised tyre turning with the chassis running, because he is not about to disassemble the motion and attempt to remove the wheel and turn it on a lathe.

The model is also likely to spent a couple of years in primer because we will wait until the real Welsh Pony is restored to steam to be certain of the correct livery.

Remember the Golden Rule of modelling. Never - ever - second-guess the FR!

Saturday 4 January 2014

Casting Couches

I'm very pleased with the way the first set of seats and tables for the Super Barns have cast and how well they've fitted inside the carriage.

The intention behind the design was that they could butt up against each other and each of the seat backs / tables be correctly positioned between the window pillars, and by and large it as worked with just a little bit of filing required on a couple of the sets.

I'd better cast another two sets now I suppose...

The intention behind the design was that they could butt up against each other and each of the seat backs / tables be correctly positioned between the window pillars, and by and large it as worked with just a little bit of filing required on a couple of the sets.

I'd better cast another two sets now I suppose...

Thursday 2 January 2014

Ball Games

A most important consideration with a brass locomotive kit is to add as much extra weight as you can wherever you can.

In the case of Welsh Pony it means stuffing it into the empty space in the saddle tank and also filling the voids inside the firebox and the smokebox.

This was not as easy as it sounds, however, because they have both been soldered into position on the frame.

The only way to add weight was to drill a small hole and fill them with tiny metal balls - known to the model trade as liquid lead - but getting it in there was quite a challenge.

It proved impossible to pour it in and Himself resorted to dropping them in one by one with a pair of tweezers!

Getting the shot into the saddle tank was much more straightforward. It could be poured and fixed in place with a coating of glue.

It won't be as heavy as the old Langley white metal Englands but this should give Welsh Pony a bit more grunt than it would otherwise have.

In the case of Welsh Pony it means stuffing it into the empty space in the saddle tank and also filling the voids inside the firebox and the smokebox.

This was not as easy as it sounds, however, because they have both been soldered into position on the frame.

The only way to add weight was to drill a small hole and fill them with tiny metal balls - known to the model trade as liquid lead - but getting it in there was quite a challenge.

It proved impossible to pour it in and Himself resorted to dropping them in one by one with a pair of tweezers!

Getting the shot into the saddle tank was much more straightforward. It could be poured and fixed in place with a coating of glue.

It won't be as heavy as the old Langley white metal Englands but this should give Welsh Pony a bit more grunt than it would otherwise have.

Subscribe to:

Posts (Atom)