It's very satisfying to get on with a job you've spent weeks procrastinating about.

The job in this case is the detail on the back of the DZ doors. The bit inside the wagon. The bit you could get away without doing if you always modelled the wagons with a full load.

Aye, there's the rub.

Finally my modelling conscience got the better of me and I decided it really would be best to try and include these details if I possibly could.

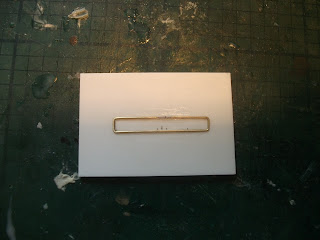

This picture shows you the bits in question. You'll see that the detail on the inside is the reverse of that on the outside of the doors.

You may remember that I am making the wagon sides in open moulds, which mean the backs are flat. You could have the detail on both sides if you used a two-part mould but my casting skills are not at that stage yet.

So the solution I've come up with is to make some very thin pieces to stick on the back of the wagon sides which hopefully will give the right effect.

The long sausage shaped lumps in the middle are simple enough but I reckoned the challenge was going to be that prominent outer ring.

What I decided on in the end was to make a loop of brass wire - soldering the joint - and then filing down one side of it so that it has a half-round profile when it is glued onto the back of the wagon doors.

Then I made the centre lumps using half-round styrene and stuck them in place in the middle. Here you see them stuck onto a piece of thick styrene to make the casting master.

The theory is that when I come to make the production copies in the mould the sheet of plastic I press onto the back of the wet resin will form a very thin skin across the back of these three parts.

This means I should be able to trim around the edge of the outer ring and glue it in place as one piece. Hopefully you will not notice the skin connecting the outer ring and the middle lumps.

Subscribe to:

Post Comments (Atom)

No comments:

Post a Comment