For the last post of 2017 I'll bring our modelling review of the year up to date.

October

Himself was steadily getting on with the top coats on the Superbarn 118 between other jobs.

He had many tasks on the go including fixing the last two bungalows in place and beginning the task of landscaping around them.

It was such a relief to have finally got all the houses built - a project which had taken many years to bring to fruition.

We also got round to purchasing a chassis to put our 3D printed Lilla body on.

At this stage it still needed some material cleared away from beneath the saddle tank which explains why it is sitting at a very racy angle.

November

There was still the need to paint the bungalows before they could be fixed in place on the layout.

The last of them was the most challenging of the lot because one wall has stone cladding which was very well represented by Himself.

The only shame was that this effect is mostly hidden from the viewing public at exhibitions because this is the side which faces the operators.

There was more work on Lilla.

The Minitrains chassis was improved with some new slidebars from RT Models and Himself also carefully filed down the fly cranks to remove the very large balance weights.

While he was doing all that I was busy earning a little money fulfilling a promise to build some of my resin SAR wagon kits for a customer.

December

As we moved into the final month of the year Himself set to with the task of painting Lilla which we're going to finish in its Penrhyn Quarry Railway lined black livery.

Currently he is engaged in the very careful and patient task of lining it out.

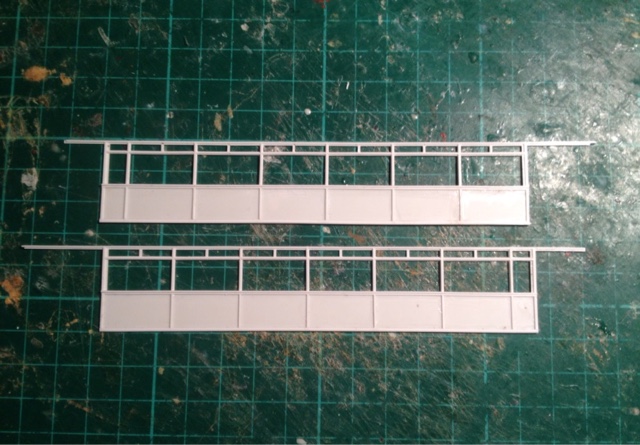

The project on my workbench at the moment is to bring our WHR carriage fleet up to date with the latest of the saloons 2047 which I am building from scratch in styrene.

So all that remains is for us to wish you all the best for 2018 and thank you for visiting the blog or keeping up with what we're up to by following us on Facebook or Twitter,

We'll be taking both Bron Hebog and Dduallt out on the rode during the year ahead and we look forward to seeing you there - full details are on the Exhibition Diary page.