It's lovely to be able to sing the praises of a trader who has provided exceptional customer service.

You may remember me blogging last week about my latest purchase - a Brian Madge kit for a cabless Quarry Hunslet - and our plans to attempt to transform it into a new model of Britomart.

I mentioned that Britomart wears a later design of frames with a flat bottom at the firebox end as opposed to the upward slope on the earlier Alice class engines.

Completely unbidden, Brian milled a replacement set of frames to the new design as well as a replacement footplate and buffer beams of the correct profile for the adopted FR engine.

Friday, 31 August 2012

Wednesday, 29 August 2012

MOTW - River Bridge

I think its time we featured another structure on Model Of The Week.

This is the stone arched bridge over the Afon Cwm Cloch just north of Beddgelert station.

I thought you might like to see some shots of how Himself made it.

As you can see below the bridge was built as a sub-assembly, so if could be completed and painted before it was fixed in place and the embankment built around it.

The faces of the bridge and the wing walls were made with a plywood base with embossed card bonded on top.

Off-cuts of plain styrene were glued along the tops to form the cappings.

You can't quite see in this picture, unfortunately, but the brick pattern styrene sheet was glued on at an angle under the arch to create the correct diagonal effect.

Here it is in position beneath the trackbed with the river being formed- the rocks, in case you're wondering, are proper, actual pebbles.

The model was finished off with another fabulous paint job by our Artistic Director.

If you haven't discovered it yet he has written a How To guide describing his technique with acrylic paints on our structures. You'll find it in the menu over on the right hand side of the page.

This is the stone arched bridge over the Afon Cwm Cloch just north of Beddgelert station.

I thought you might like to see some shots of how Himself made it.

As you can see below the bridge was built as a sub-assembly, so if could be completed and painted before it was fixed in place and the embankment built around it.

The faces of the bridge and the wing walls were made with a plywood base with embossed card bonded on top.

Off-cuts of plain styrene were glued along the tops to form the cappings.

You can't quite see in this picture, unfortunately, but the brick pattern styrene sheet was glued on at an angle under the arch to create the correct diagonal effect.

Here it is in position beneath the trackbed with the river being formed- the rocks, in case you're wondering, are proper, actual pebbles.

The model was finished off with another fabulous paint job by our Artistic Director.

If you haven't discovered it yet he has written a How To guide describing his technique with acrylic paints on our structures. You'll find it in the menu over on the right hand side of the page.

Monday, 27 August 2012

Reverse Image

The first few casts of the lumps on the back of the DZ doors have been popped out of the moulds.

Here are three of them resting in place on the rear of one of the wagon sides.

Please bear in mind they've only been roughly positioned for the photograph - I know that some of them are a little skew-whiff, and the side door unit still has some casting flash to be cleaned up - but I think it gives a fair impression of how they're going to look.

What do you think? Effective?

Here are three of them resting in place on the rear of one of the wagon sides.

Please bear in mind they've only been roughly positioned for the photograph - I know that some of them are a little skew-whiff, and the side door unit still has some casting flash to be cleaned up - but I think it gives a fair impression of how they're going to look.

What do you think? Effective?

Saturday, 25 August 2012

Variations On A Theme

The FR and WHR may be very different railways but one trait they most certainly share is that no locomotive or item of rolling stock stays the same for long, and the DZ wagons are no exception to this rule.

The wagons that arrived from South African were, it's fair to say, not in A1 condition. Volunteers spent many hours with angle grinders and paint brushes tarting them up and getting them fit to run, but at least one of them has now fallen into the clutches of Boston Lodge Works for a full overhaul.

And guess what! It doesn't look like the rest any more.

The biggest change is in the ends, which have been completely replaced with much chunkier sections which are also designed to be removable. The posts between the side doors are also different to the type of DZ I've already built in that they are of a T section rather a U section.

I felt I had little choice but to make a second design of wagon representing these alterations for use on Bron Hebog.

This meant starting again by making a new master from three individual door casts connected into one piece with the alternate post design.

Here it is mounted on styrene sheet ready to have a moulding box built up around it and buried in RTV compound.

The next step will be to make a master for the ends.

The wagons that arrived from South African were, it's fair to say, not in A1 condition. Volunteers spent many hours with angle grinders and paint brushes tarting them up and getting them fit to run, but at least one of them has now fallen into the clutches of Boston Lodge Works for a full overhaul.

And guess what! It doesn't look like the rest any more.

The biggest change is in the ends, which have been completely replaced with much chunkier sections which are also designed to be removable. The posts between the side doors are also different to the type of DZ I've already built in that they are of a T section rather a U section.

I felt I had little choice but to make a second design of wagon representing these alterations for use on Bron Hebog.

This meant starting again by making a new master from three individual door casts connected into one piece with the alternate post design.

Here it is mounted on styrene sheet ready to have a moulding box built up around it and buried in RTV compound.

The next step will be to make a master for the ends.

Thursday, 23 August 2012

MOTW - 104

A piece of classic '80s heritage on Model Of The Week for you this time.

It seems strange how 104 has survived the retro-rebuilding / upgrading of the Barns in recent years and is still running around pretty much the same condition as when it was given a radical makeover in mid'80's, losing its classic Barn toplights and louvred windows in favour of larger, rubber-edged panes.

104 is, of course, the doyen of the Barn programme of the 1960's. You could be forgiven for thinking it was the (now scrapped) Observation Carr 100 that was the first, but this composite saloon emerged a year ahead of it with the original running number 24.

This is my second model of 104 which I made because my carriage building technique had advanced considerably from the first batch of carriages I built in my teens in the early '90s.

One of the big improvements was the much chunkier corridor connections with styrene strips formed into channel and shaped to look like the folded rubber on the real carriages.

On this second generation of carriages I also began adding an additional layer of strip on the window pillars which adds a much finer degree of detailing and a crisper look the carriage overall.

In its own way I think 104 has become an FR design classic - an elegant comprise between the original Barn outline and the modernist Tin Carrs of the '70s - and I think I'll quite miss it when it is inevitably (?) chopped up for firewood and something new placed upon its underframe.

It seems strange how 104 has survived the retro-rebuilding / upgrading of the Barns in recent years and is still running around pretty much the same condition as when it was given a radical makeover in mid'80's, losing its classic Barn toplights and louvred windows in favour of larger, rubber-edged panes.

104 is, of course, the doyen of the Barn programme of the 1960's. You could be forgiven for thinking it was the (now scrapped) Observation Carr 100 that was the first, but this composite saloon emerged a year ahead of it with the original running number 24.

This is my second model of 104 which I made because my carriage building technique had advanced considerably from the first batch of carriages I built in my teens in the early '90s.

One of the big improvements was the much chunkier corridor connections with styrene strips formed into channel and shaped to look like the folded rubber on the real carriages.

On this second generation of carriages I also began adding an additional layer of strip on the window pillars which adds a much finer degree of detailing and a crisper look the carriage overall.

In its own way I think 104 has become an FR design classic - an elegant comprise between the original Barn outline and the modernist Tin Carrs of the '70s - and I think I'll quite miss it when it is inevitably (?) chopped up for firewood and something new placed upon its underframe.

Tuesday, 21 August 2012

What Are We Going To Do With Alice?

I've set Himself a new challenge - I don't think he's too pleased about it!

He's been presented with one of Brian Madge's new kits for the diminutive 'Quarry Hunslet'.

What's very exciting about this new entry in the 009 market is it has proper outside frames. For the last 20 years our model of Britomart has been running around on an ancient Arnold N gauge chassis with us trying to pretend that we never noticed its very obvious inside frames.

The challenge comes from the kit being designed to represent Velinheli, one of the cab-less members of the 'Alice' class, whereas Britomart not only has a cab but also a subtle difference in the outline of the frames at the rear of the loco.

Himself has been investigating whether there is any possibility of being able to simply transplant Brian's outside framed chassis into our existing Chivers body.

Unfortunately it appears not!

The only way of fitting the new chassis would be to double up with the new footplate frame mounted beneath the existing whitemetal one, which would be far too thick.

It's also doubtful whether the motor unit would fit inside the existing saddle tank without an awful lot of metal being carved away.

Understandably, Himself is reluctant to rip apart our current Britomart and start hacking away at it with no guarantee the transplant is going to be successful, so I suspect our next move will be to obtain another Chivers Quarry Hunslet and create a mongrel loco with bits taken from both the kits.

I shall keep you in touch with progress.

He's been presented with one of Brian Madge's new kits for the diminutive 'Quarry Hunslet'.

What's very exciting about this new entry in the 009 market is it has proper outside frames. For the last 20 years our model of Britomart has been running around on an ancient Arnold N gauge chassis with us trying to pretend that we never noticed its very obvious inside frames.

The challenge comes from the kit being designed to represent Velinheli, one of the cab-less members of the 'Alice' class, whereas Britomart not only has a cab but also a subtle difference in the outline of the frames at the rear of the loco.

Himself has been investigating whether there is any possibility of being able to simply transplant Brian's outside framed chassis into our existing Chivers body.

Unfortunately it appears not!

The only way of fitting the new chassis would be to double up with the new footplate frame mounted beneath the existing whitemetal one, which would be far too thick.

It's also doubtful whether the motor unit would fit inside the existing saddle tank without an awful lot of metal being carved away.

Understandably, Himself is reluctant to rip apart our current Britomart and start hacking away at it with no guarantee the transplant is going to be successful, so I suspect our next move will be to obtain another Chivers Quarry Hunslet and create a mongrel loco with bits taken from both the kits.

I shall keep you in touch with progress.

Labels:

Brian Madge Kits,

Britomart,

Chivers Finelines,

Quarry Hunslet

Sunday, 19 August 2012

Bumps On The Behind

It's very satisfying to get on with a job you've spent weeks procrastinating about.

The job in this case is the detail on the back of the DZ doors. The bit inside the wagon. The bit you could get away without doing if you always modelled the wagons with a full load.

Aye, there's the rub.

Finally my modelling conscience got the better of me and I decided it really would be best to try and include these details if I possibly could.

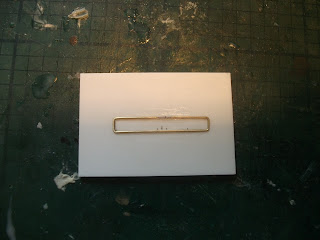

This picture shows you the bits in question. You'll see that the detail on the inside is the reverse of that on the outside of the doors.

You may remember that I am making the wagon sides in open moulds, which mean the backs are flat. You could have the detail on both sides if you used a two-part mould but my casting skills are not at that stage yet.

So the solution I've come up with is to make some very thin pieces to stick on the back of the wagon sides which hopefully will give the right effect.

The long sausage shaped lumps in the middle are simple enough but I reckoned the challenge was going to be that prominent outer ring.

What I decided on in the end was to make a loop of brass wire - soldering the joint - and then filing down one side of it so that it has a half-round profile when it is glued onto the back of the wagon doors.

Then I made the centre lumps using half-round styrene and stuck them in place in the middle. Here you see them stuck onto a piece of thick styrene to make the casting master.

The theory is that when I come to make the production copies in the mould the sheet of plastic I press onto the back of the wet resin will form a very thin skin across the back of these three parts.

This means I should be able to trim around the edge of the outer ring and glue it in place as one piece. Hopefully you will not notice the skin connecting the outer ring and the middle lumps.

The job in this case is the detail on the back of the DZ doors. The bit inside the wagon. The bit you could get away without doing if you always modelled the wagons with a full load.

Aye, there's the rub.

Finally my modelling conscience got the better of me and I decided it really would be best to try and include these details if I possibly could.

This picture shows you the bits in question. You'll see that the detail on the inside is the reverse of that on the outside of the doors.

You may remember that I am making the wagon sides in open moulds, which mean the backs are flat. You could have the detail on both sides if you used a two-part mould but my casting skills are not at that stage yet.

So the solution I've come up with is to make some very thin pieces to stick on the back of the wagon sides which hopefully will give the right effect.

The long sausage shaped lumps in the middle are simple enough but I reckoned the challenge was going to be that prominent outer ring.

What I decided on in the end was to make a loop of brass wire - soldering the joint - and then filing down one side of it so that it has a half-round profile when it is glued onto the back of the wagon doors.

Then I made the centre lumps using half-round styrene and stuck them in place in the middle. Here you see them stuck onto a piece of thick styrene to make the casting master.

The theory is that when I come to make the production copies in the mould the sheet of plastic I press onto the back of the wet resin will form a very thin skin across the back of these three parts.

This means I should be able to trim around the edge of the outer ring and glue it in place as one piece. Hopefully you will not notice the skin connecting the outer ring and the middle lumps.

Friday, 17 August 2012

Mass Production

I've been busy with the casting resin in the last couple of days and here is the result; the first batch of DZ wagon body parts.

There are enough bits for 5 bodyshells here. Some of the casts are just fresh from the moulds and are still wearing their big skirts of excess resin which gets squeezed out at the sides when the back-flattening sheet is applied.

The good thing about casting is that it is only a five minute job to mix up some resin and pour it in the mould and then you can get on with something else while it cures, which means you can fit it around other household chores such as supervising 5 year old daughters.

I'm pretty pleased with how these have turned out. Swishing a cocktail stick around the resin straight after it is poured is resulting in casts which are 99% air bubble-free, and those that do crop up can be easily sorted with a wee bit of Milliput.

Once the bogies, brake wheels and gubbins which are being etched for me by Narrow Planet are ready I can get them on the market properly.

There are enough bits for 5 bodyshells here. Some of the casts are just fresh from the moulds and are still wearing their big skirts of excess resin which gets squeezed out at the sides when the back-flattening sheet is applied.

The good thing about casting is that it is only a five minute job to mix up some resin and pour it in the mould and then you can get on with something else while it cures, which means you can fit it around other household chores such as supervising 5 year old daughters.

I'm pretty pleased with how these have turned out. Swishing a cocktail stick around the resin straight after it is poured is resulting in casts which are 99% air bubble-free, and those that do crop up can be easily sorted with a wee bit of Milliput.

Once the bogies, brake wheels and gubbins which are being etched for me by Narrow Planet are ready I can get them on the market properly.

Wednesday, 15 August 2012

MOTW - Van 51

I've got another one of our multiple models to show you this week.

We have two versions of Van 51 / Van 1 which is another of those FR vehicles which has been given a new look and a new identity over the years.

This is the more modern of them, as P-Way brake van 51.

The model was scratch built in styrene to show the van as it appeared for the last decade or so in a livery not dissimilar to that adopted by BR's engineers fleet at one time and which suited it rather well, I think. It was built up on a Dundas four wheel chassis kit.

Van 1 was constructed in 1964 by the volunteers of the Midland Group of the FR Society. In its early years it was used as a passenger carriage at the peak of summer traffic.

At that time it looked much larger with the full height bodywork carried forwards to form a covered entrance vestibule, which was reduced to an open platform during a rebuild in the mid-80's making it look much more like one of the original FR four wheel vans which has been converted from quarrymens carriages.

In the 90's it was given a new number to accommodate a replica of a four wheeled double-balconied van which took the number 1, although it too later surrendered it to the reborn 'curly rood van'.

In its original condition the van formed part of the historic first steam train to return to Blaenau in 1982, hauled by Blanche. By now the all over green livery it first wore had been replaced by cherry red. Our other model of it portrays it in this condition and will no doubt be a future Model Of The Week subject.

We have two versions of Van 51 / Van 1 which is another of those FR vehicles which has been given a new look and a new identity over the years.

This is the more modern of them, as P-Way brake van 51.

The model was scratch built in styrene to show the van as it appeared for the last decade or so in a livery not dissimilar to that adopted by BR's engineers fleet at one time and which suited it rather well, I think. It was built up on a Dundas four wheel chassis kit.

Van 1 was constructed in 1964 by the volunteers of the Midland Group of the FR Society. In its early years it was used as a passenger carriage at the peak of summer traffic.

At that time it looked much larger with the full height bodywork carried forwards to form a covered entrance vestibule, which was reduced to an open platform during a rebuild in the mid-80's making it look much more like one of the original FR four wheel vans which has been converted from quarrymens carriages.

In the 90's it was given a new number to accommodate a replica of a four wheeled double-balconied van which took the number 1, although it too later surrendered it to the reborn 'curly rood van'.

In its original condition the van formed part of the historic first steam train to return to Blaenau in 1982, hauled by Blanche. By now the all over green livery it first wore had been replaced by cherry red. Our other model of it portrays it in this condition and will no doubt be a future Model Of The Week subject.

Monday, 13 August 2012

That Swing Thing

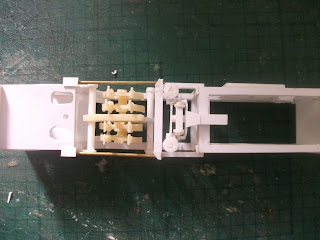

It's time to put together the second prototype DZ wagon to see if the changes I've made to the position of the 'wee dangly bits' have worked.

The problem, you will recall, was two-fold. Not only were they in slightly the wrong position, they also stopped the bogies from swinging as far as I felt they needed to.

That's not necessarily a problem on Bron Hebog - the layout is so large by 009 standards that we have very easy curves - but as I am intending to sell the castings as a basic kit I need to take into account that some buyers may have much sharper bends on their layouts and the wagons need be able to cope with those.

These castings are not very challenging to put together, as you can see here.

The first stage is to attach the two sides to the floor / chassis unit which has been designed so the bottom of the sides are fixed flush with the bottom of the chassis frame.

I use rapid set epoxy resin, rather than superglue, to give myself plenty of adjusting time.

And when those are solid the end pieces can be glued on in a similar fashion.

See, I told you it was simple!

The bogies are designed to pivot on a 10BA bolt put through a hole in the floor and retained by a nut. (Apologies if this is all a bid bleedin' obvious.)

The bogies you see here are a pair of Worsley Works etches we had lying around spare, with a brass coupling shaft added on and fitted with 2mm 'top hat' brass bushes which I have filed down aggressively on the outside to maximise the angle the bogies can swing.

I think that should be quite sufficient for a wagon which is only 10cm long. Surely to goodness no one has curves tighter than that, do they?

The problem, you will recall, was two-fold. Not only were they in slightly the wrong position, they also stopped the bogies from swinging as far as I felt they needed to.

That's not necessarily a problem on Bron Hebog - the layout is so large by 009 standards that we have very easy curves - but as I am intending to sell the castings as a basic kit I need to take into account that some buyers may have much sharper bends on their layouts and the wagons need be able to cope with those.

These castings are not very challenging to put together, as you can see here.

The first stage is to attach the two sides to the floor / chassis unit which has been designed so the bottom of the sides are fixed flush with the bottom of the chassis frame.

I use rapid set epoxy resin, rather than superglue, to give myself plenty of adjusting time.

And when those are solid the end pieces can be glued on in a similar fashion.

See, I told you it was simple!

The bogies are designed to pivot on a 10BA bolt put through a hole in the floor and retained by a nut. (Apologies if this is all a bid bleedin' obvious.)

The bogies you see here are a pair of Worsley Works etches we had lying around spare, with a brass coupling shaft added on and fitted with 2mm 'top hat' brass bushes which I have filed down aggressively on the outside to maximise the angle the bogies can swing.

I think that should be quite sufficient for a wagon which is only 10cm long. Surely to goodness no one has curves tighter than that, do they?

Saturday, 11 August 2012

Lending Library

There's not been a lot of modelling done this past week, but plenty of reading.

Himself has been up here to convalesce from the exertions of helping with the annual Kids Training Week on the FR. (According to the teenagers he was, apparently, 'cool', which he seems rather pleased about.)

He also brought with him some new books he bought in the railway's shop at Portmadog which I've been having a good look at.

One which may be of particular interest to blog readers is the latest offering from Middleton Press in their Great Railway Eras series, this time with all colour snaps of the FR between 1955 and 1982.

Some may question the appropriateness of the phrase 'Great Railway Eras' in this case because this period - or at least the second half of it - is widely viewed as the FR's Ugly Railway Era.

This was the time when Merddin Emrys was given a radical rebuild with a new boiler and emerged looking almost anorexic. The new Earl of Merioneth, on the other hand, gorged on steel plate and gave a passable impression of two army tanks parked back to back.

Historic vintage carriages were stripped of panelling and covered in a monotonous red livery, while redundant road tankers doubled as water towers and old oil drums became platform rubbish bins.

But I loved it! This is the FR of my childhood. There's no denying the railway looks better, is more varied and makes so much more of its unique heritage these days, but nostalgia is a powerful emotion and we all have a soft spot for things we remember from our younger days.

If you're an FR anorak then I'm sure you will quickly spot some of the caption howlers in the book. There are 3 very obvious ones I've spotted so far: A shot of Prince on the mineral line at Minffordd which the book says is 1980 but which is so obviously the late 1960's because of the altered frames beneath the saddle tank. There is Merddin on Cei Mawr with a train of vintage stock in green and ivory livery. 1971 it says. I don't think so! Ditto a snap of Linda and Blanche at Harbour with carriages in the same colour scheme which the author also tries to tell us is 1971.

I point this out not because I want to look like an FR smart-arse but because for modellers these are important details. FR locos and carriages have been altered in subtle ways so frequently over the years that you have to look at a lot of pictures when doing your research and caption errors like this can be confusing and misleading.

Some of the pictures are also a little fuzzy which is perhaps a consequence of the original camerawork rather than the reproduction in the book.

Despite these niggles, however, I really enjoyed the book and would say it's an essential element of an FR enthusiasts library.

Himself has been up here to convalesce from the exertions of helping with the annual Kids Training Week on the FR. (According to the teenagers he was, apparently, 'cool', which he seems rather pleased about.)

He also brought with him some new books he bought in the railway's shop at Portmadog which I've been having a good look at.

One which may be of particular interest to blog readers is the latest offering from Middleton Press in their Great Railway Eras series, this time with all colour snaps of the FR between 1955 and 1982.

Some may question the appropriateness of the phrase 'Great Railway Eras' in this case because this period - or at least the second half of it - is widely viewed as the FR's Ugly Railway Era.

This was the time when Merddin Emrys was given a radical rebuild with a new boiler and emerged looking almost anorexic. The new Earl of Merioneth, on the other hand, gorged on steel plate and gave a passable impression of two army tanks parked back to back.

Historic vintage carriages were stripped of panelling and covered in a monotonous red livery, while redundant road tankers doubled as water towers and old oil drums became platform rubbish bins.

But I loved it! This is the FR of my childhood. There's no denying the railway looks better, is more varied and makes so much more of its unique heritage these days, but nostalgia is a powerful emotion and we all have a soft spot for things we remember from our younger days.

If you're an FR anorak then I'm sure you will quickly spot some of the caption howlers in the book. There are 3 very obvious ones I've spotted so far: A shot of Prince on the mineral line at Minffordd which the book says is 1980 but which is so obviously the late 1960's because of the altered frames beneath the saddle tank. There is Merddin on Cei Mawr with a train of vintage stock in green and ivory livery. 1971 it says. I don't think so! Ditto a snap of Linda and Blanche at Harbour with carriages in the same colour scheme which the author also tries to tell us is 1971.

I point this out not because I want to look like an FR smart-arse but because for modellers these are important details. FR locos and carriages have been altered in subtle ways so frequently over the years that you have to look at a lot of pictures when doing your research and caption errors like this can be confusing and misleading.

Some of the pictures are also a little fuzzy which is perhaps a consequence of the original camerawork rather than the reproduction in the book.

Despite these niggles, however, I really enjoyed the book and would say it's an essential element of an FR enthusiasts library.

Thursday, 9 August 2012

Left A Bit, Right A Bit

I've been working on what you might call the 'production' version of the DZ wagon sides.

Putting together the prototype wagon revealed very few issues other than the positioning of the 'wee dangly bits' that hang from the frame and stop the doors swinging down far when they are lowered.

It turns out that these DZ's, in common with most narrow gauge rolling stock I've ever tried to model, are not nice and symmetrical.

As you may recall from previous posts I began the DZ project by making one of the three sets of doors which make up each side and then casting copies of that which I joined together to make one complete wagon side.

The original cast came complete with dangly bits which meant that when three of them were put together they were spaced identically, and evenly, on each third of the wagon.

The catch is that the real wagons, it turns out, are not so straightforward. Himself examined a couple of them at Dinas and noticed that the 2nd and 5th WDB (wee dangly bit) are positioned differently relative to the rest of the door unit.

You can see in this picture below of one of the original wagon sides (bottom) and one of the new ones (top)how the positions differ.

Not only that but on the model they were slightly restricting the bogie swing in their original positions.

Fortunately it's been relatively simple to correct the error. I went back to the master and simply chopped the offending DB's off, and repositioned them. Resin parts stick excellently with superglue and as the master is stuck onto a backing sheet of styrene they're not about to get knocked off.

All that was left was to carve off the old hinge detail and replace with new styrene strip and then produce a new silicone mould and get casting again.

Putting together the prototype wagon revealed very few issues other than the positioning of the 'wee dangly bits' that hang from the frame and stop the doors swinging down far when they are lowered.

It turns out that these DZ's, in common with most narrow gauge rolling stock I've ever tried to model, are not nice and symmetrical.

As you may recall from previous posts I began the DZ project by making one of the three sets of doors which make up each side and then casting copies of that which I joined together to make one complete wagon side.

The original cast came complete with dangly bits which meant that when three of them were put together they were spaced identically, and evenly, on each third of the wagon.

The catch is that the real wagons, it turns out, are not so straightforward. Himself examined a couple of them at Dinas and noticed that the 2nd and 5th WDB (wee dangly bit) are positioned differently relative to the rest of the door unit.

You can see in this picture below of one of the original wagon sides (bottom) and one of the new ones (top)how the positions differ.

Not only that but on the model they were slightly restricting the bogie swing in their original positions.

Fortunately it's been relatively simple to correct the error. I went back to the master and simply chopped the offending DB's off, and repositioned them. Resin parts stick excellently with superglue and as the master is stuck onto a backing sheet of styrene they're not about to get knocked off.

All that was left was to carve off the old hinge detail and replace with new styrene strip and then produce a new silicone mould and get casting again.

Tuesday, 7 August 2012

MOTW - NG-Y Ballast Wagon

A treat for South African NG fans this week, our featured model is one of our pair of the WHR's ex-SAR ballast wagons.

In my opinion these wagons are a 'must have' for any model of the modern WHR because they were so essential to the effort to rebuild the line from Caernarfon to Porthmadog.

Ours are scratch built from styrene and it took a while to get around to making them because I didn't have access to any drawings for the NG Y design. In the end I took a tape measure to one of them myself along with a copious amount of pictures taken from every angle.

A big help in getting them to look right is the availability of U section styrene produced in a wide range of sizes by Evergreen which was used for the straps along the side of the hoppers, the Z struts at each end and the inner parts of the main frames.

Another important finishing touch is the distinctive wheels used for the hand brakes and the controls for the ballast chutes which I had custom etched.

Himself made use of his airbrush for the weathering effects to make them look suitably used.

We've perhaps overdone it a little with the load - some viewers at exhibitions have commented that they would be over the weight limit - but I have to say I have seen pictures of them looking pretty full when in use on construction trains.

I've also scratch built a handful of these wagons for other modellers in both 4mm and 7mm scale. With the development of the resin DZ's progressing well I would be interested in assessing whether there would be any demand for me working on a kit for these NG Y monsters. If you would be, please do let me know.

In my opinion these wagons are a 'must have' for any model of the modern WHR because they were so essential to the effort to rebuild the line from Caernarfon to Porthmadog.

Ours are scratch built from styrene and it took a while to get around to making them because I didn't have access to any drawings for the NG Y design. In the end I took a tape measure to one of them myself along with a copious amount of pictures taken from every angle.

A big help in getting them to look right is the availability of U section styrene produced in a wide range of sizes by Evergreen which was used for the straps along the side of the hoppers, the Z struts at each end and the inner parts of the main frames.

Another important finishing touch is the distinctive wheels used for the hand brakes and the controls for the ballast chutes which I had custom etched.

Himself made use of his airbrush for the weathering effects to make them look suitably used.

We've perhaps overdone it a little with the load - some viewers at exhibitions have commented that they would be over the weight limit - but I have to say I have seen pictures of them looking pretty full when in use on construction trains.

I've also scratch built a handful of these wagons for other modellers in both 4mm and 7mm scale. With the development of the resin DZ's progressing well I would be interested in assessing whether there would be any demand for me working on a kit for these NG Y monsters. If you would be, please do let me know.

Sunday, 5 August 2012

Tube Train

It's mostly wee bits and pieces which are left on the KMX tamper now, except for the big matter of the roof which I'm going to sub-contract out to Himself.

Just because they're smaller doesn't necessarily mean they're quick though.

These air tanks which live under the cab floor took an hour to make and fit.

I make them using a length of styrene tube. It then has a square piece of sheet glued onto either end. Once the bond is solid it is trimmed as much as possible with the scalpel and then finished with a file and emery paper, rounding off the shoulders at each end.

Finally at each end I curled a very thin strip of styrene around it - clamping the ends together with the tip of the tweezers - and running glue all around it. Sometimes the strip will snap when it's being bent around or when the glue hits it, but you always get there in the end with a bit of perseverance.

I did the same with some smaller diameter, single ended ones, beneath the other cab.

(Single ended only because you can't see the other end on the model, that is)

Another job to be ticked off was converting the trailing bogie from the Kato shorty chassis so that it can be secured with a 10BA bolt.

Yes, you've guessed it, another use found for Evergreen tubing. It's handy stuff to have in stock.

Just because they're smaller doesn't necessarily mean they're quick though.

These air tanks which live under the cab floor took an hour to make and fit.

I make them using a length of styrene tube. It then has a square piece of sheet glued onto either end. Once the bond is solid it is trimmed as much as possible with the scalpel and then finished with a file and emery paper, rounding off the shoulders at each end.

Finally at each end I curled a very thin strip of styrene around it - clamping the ends together with the tip of the tweezers - and running glue all around it. Sometimes the strip will snap when it's being bent around or when the glue hits it, but you always get there in the end with a bit of perseverance.

I did the same with some smaller diameter, single ended ones, beneath the other cab.

(Single ended only because you can't see the other end on the model, that is)

Another job to be ticked off was converting the trailing bogie from the Kato shorty chassis so that it can be secured with a 10BA bolt.

Yes, you've guessed it, another use found for Evergreen tubing. It's handy stuff to have in stock.

Friday, 3 August 2012

The Squeezy Bits

The trickiest bit of making the KMX tamper is the hydraulic gubbins in the middle.

While I am able to cheat by using resin castings for the tamper head, the lifting and lining bits from the Britannia Pacific kits don't look anything like the appendages hanging from the WHR's heavily rebuilt machine. So I have to make them myself.

This is rather complicated - although satisfying - process.

Various different thicknesses of Evergreen styrene rod are employed to make the hydraulic arms and to bodge up something to represent the horizontal guide wheels / grabbing things at the bottom.

This involves slicing such fine discs of plastic tube that would impress a prize winning salami maker!

There's also a frame that they're attached to which has to be fabricated and finally something to represent the shaft beneath. This should run all the way to a point near the bogie beneath the engine compartment, but I can't do that on the model because the Kato chassis has to be inserted / removed from beneath.

I'm starting to feel that I've really broken the back of this project now, but there's still a tremendous amount of fine detailing to be added all around the body, not to mention a lot of cosmetic surgery on the bogies.

While I am able to cheat by using resin castings for the tamper head, the lifting and lining bits from the Britannia Pacific kits don't look anything like the appendages hanging from the WHR's heavily rebuilt machine. So I have to make them myself.

This is rather complicated - although satisfying - process.

Various different thicknesses of Evergreen styrene rod are employed to make the hydraulic arms and to bodge up something to represent the horizontal guide wheels / grabbing things at the bottom.

This involves slicing such fine discs of plastic tube that would impress a prize winning salami maker!

There's also a frame that they're attached to which has to be fabricated and finally something to represent the shaft beneath. This should run all the way to a point near the bogie beneath the engine compartment, but I can't do that on the model because the Kato chassis has to be inserted / removed from beneath.

I'm starting to feel that I've really broken the back of this project now, but there's still a tremendous amount of fine detailing to be added all around the body, not to mention a lot of cosmetic surgery on the bogies.

Wednesday, 1 August 2012

MOTW - 102

This vehicle marked the start of a new wave in Observation Carriage design and furnishing standards on the FR.

Built in 2005 the most obvious change was the return to a single window pillar at the observation end, with a pair of large, square windows, as opposed to the triple arrangement that had become so familiar over the previous 40 years.

Passengers also would have noticed the generously upholstered freestanding chairs in this compartment in contrast to the fixed, swivelling seats in the first generation of Barns.

For carriage-spotters like me other details stood out like the wooden frame half droplights (which first appeared on the rebuilt 106) which were a new challenge to model, and the return to squared corners in the windows rather than the rounded rubber beading which the older carriages had acquired over the years.

102 also heralded a change in the look of our carriage fleet. It was around this time that Boston Lodge began outshopping carriages with bright, washing-power white roofs. They don't stay looking like this for long, of course, especially not since the FR began to reintroduce coal firing.

We tend to finish our models in something approaching ex-works condition, so our 102 still has a very pale roof.

The picture here, which was taken during the Railex exhibition back in May, also shows 102 sporting the rather fabulous new gold transfers which we had commissioned from Precision Decals. 102 was also the first observation carr. to wear the old-style FR monogram with the branding Ffestiniog First underneath.

The large crest to the left, on the guards compartment, is also a Precision Decals product.

Built in 2005 the most obvious change was the return to a single window pillar at the observation end, with a pair of large, square windows, as opposed to the triple arrangement that had become so familiar over the previous 40 years.

Passengers also would have noticed the generously upholstered freestanding chairs in this compartment in contrast to the fixed, swivelling seats in the first generation of Barns.

For carriage-spotters like me other details stood out like the wooden frame half droplights (which first appeared on the rebuilt 106) which were a new challenge to model, and the return to squared corners in the windows rather than the rounded rubber beading which the older carriages had acquired over the years.

102 also heralded a change in the look of our carriage fleet. It was around this time that Boston Lodge began outshopping carriages with bright, washing-power white roofs. They don't stay looking like this for long, of course, especially not since the FR began to reintroduce coal firing.

We tend to finish our models in something approaching ex-works condition, so our 102 still has a very pale roof.

The picture here, which was taken during the Railex exhibition back in May, also shows 102 sporting the rather fabulous new gold transfers which we had commissioned from Precision Decals. 102 was also the first observation carr. to wear the old-style FR monogram with the branding Ffestiniog First underneath.

The large crest to the left, on the guards compartment, is also a Precision Decals product.

Subscribe to:

Comments (Atom)